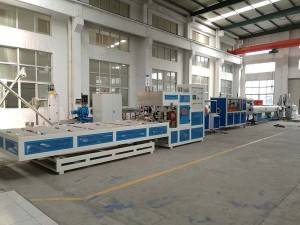

PVC Pipe Production Line

Botsa JoaleTlhaloso e qaqileng ea Sehlahisoa

| mohlala | FGE63 | FGE110 | FGE-250 | FGE315 | FGE630 | FGE800 |

| bophara ba phala | 20-63 limilimithara | 20-110 limilimithara | 75-250 limilimithara | 110-315 limilimithara | 315-630 limilimithara | 500-800 limilimithara |

| mohlala oa extruder | SJ65 | SJ75 | SJ90 | SJ90 | SJ120 | SJ120+SJ90 |

| matla a motlakase | 37kw | 55kw | 90kw | 160kw | 280kw | 280KW+160KW |

| bokhoni ba extrusion | 100kg/h | 150kg | 220kg | 400kg | 700kg | 1000kg |

bophara bo boholo PVC phala extrusion line

Mohala ona o sebelisoa haholo-holo bakeng sa ho hlahisa lipeipi tsa UPVC tse nang le li-diameter tse kholo le botenya bo fapaneng ba lebota la liphaephe likarolong tse kang tsa temo le lipeipi tsa kaho, cable layietc. Bophara bo boholo ba phala e ka ba 1200mm.

Tsela ea ho phalla ha mohala ona e le ho otla

PVC powder + additive --- kopanya---material feeder---twin screw extruder---mold le calibrator---vacuum forming machine---spraying cooling machine---huul-off machine---mochine o sehang- -- rack e ntšang kapa mochini o betsang lipeipi.

The screw of extruder e na le moralo o tsoetseng pele, o fanang ka tšireletso e matla bakeng sa polasetiki ea PVC, mme sistimi ea taolo ea Siemens PLC e etsa ts'ebetso e bonolo haholoanyane. Mokhoa oa ho ntša metsi o tla netefatsa boleng ba lipeipi tsa ho qetela tsa PVC.

Setsi sa tanka sa vacuum calibration le pholileng se nka tšepe e sa hloekang ea 304#, sistimi e nang le likarolo tse ngata e netefatsa hore boholo bo tsitsitse le ho phophola ha liphaephe; Sistimi e khethehileng ea ho futhumatsa e ntlafatsa ts'ebetso ea pholiso; Sistimi ea ho laola mocheso oa metsi ka boiketsetso e etsa hore mochini o be bohlale haholoanyane.

Bakeng sa boholo bo fapaneng ba liphaephe, mochine oa ho hula o tla amohela popane tse peli, popane e meraro, popane e mene, popane e tšeletseng e etselitsoe litlhoko tse fapaneng. Pedrail clamping e sebelisa sistimi e kopanyang ea mochini le ea pneumatic, e ts'epahalang haholoanyane ts'ebetsong

Sistimi ea ho itšeha e amohela sehahi se se nang lerōle kapa mokhoa oa ho seha polanete; Ho na le sistimi ea ho bokella lerole e netefatsang tikoloho e hloekileng ea ho sebetsa.

Lintlha tsa tekheniki

| mohlala | FGP160 | FGP250 | FGP315 | FGP630 | FGP800 |

| boholo ba phala | 50-160 limilimithara | 75-250 limilimithara | 110-315 limilimithara | 315-630 limilimithara | 500-800 limilimithara |

| extruder | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ92/188 | SJZ92/188 |

| matla a motlakase | 37kw | 55kw | 90kw | 110kw | 132kw |

| tlhahiso | 250kg | 350kg | 550kg | 600kg | 700kg |

Lihlahisoa tse khothalelitsoeng

Tse ling +-

Mochini oa ho Crusher oa polasetiki

.Sesebelisoa sa thipa se hloekisoa ka i, ported special too-steel, the clearance between thipa tools are adjustable, ha e ba lerootho ha e sebelisoa, e ka theoloa khafetsa, e ea tšoarella.

• Sebelisa likurufu tsa tšepe tse matla haholo ho tiisa lekhasi la thipa le setulo sa thipa, tse nang le matla a ho jara.

• Mabota ohle a kamore e pshatlehang a ts'oaroa ka hore a se ke a utloa molumo, kahoo ho ba le lerata le tlase la eatra

• Mofuta oa theolelo o etselitsoeng, bunker, 'mele o ka sehloohong,Sieve e ka theoloa hore e hloekisoe habonolo, e boima ka sesebelisoa sa ts'ireletso ea lerōle.

Ithute haholoanyane -

Mohala oa tlhahiso ea lipeipi tsa PP

E sebelisoa haholo bakeng sa ho hlahisa PP-R, liphaephe tsa PE tse bophara ba 16mm ~ 160mm, liphaephe tsa PE-RT tse bophara ba 16 ~ 32mm. E na le lisebelisoa tse nepahetseng tse tlase, e ka boela ea hlahisa liphaephe tsa PP-R tsa mufti-layer, lipeipi tsa fiber tsa khalase tsa PP-R, lipeipi tsa PE-RT le EVOH. Ka phihlelo ea lilemo tse ngata bakeng sa extrusion ea liphaephe tsa polasetiki, re boetse re ntlafalitse lebelo le phahameng la PP-R / PE pipe extrusion line, 'me lebelo la tlhahiso ea max e ka ba 35m / min (e thehiloeng holim'a liphaephe tsa 20mm).

Ithute haholoanyane -

Mochini o iketselitseng oa phala

1.letoto lena le ka sebetsoa Φ16-1000mm leha e le efe phaephe flaring

2.ka mokhoa o itekanetseng oa ho fana ka tube.flip tube.flaring mosebetsi

3.ka ho futhumatsa.cooling.timing.automatic.manual function

4. moralo oa modular oa likarolo

5.boholo bo nyane.lerata le tlase

6.tshebediso ya vacuum adsorption.flaring profile e hlakileng.tiisetso ea boholo

7.matla (ha a bapisoa le lihlahisoa tse tšoanang.ho boloka matla 50%)

8.e ka etsoa ho latela litlhoko tsa mosebelisi litlhaloso tse khethehileng

Ithute haholoanyane -

Mochini oa ho itšeha oa botlolo oa polasetiki o ikatisang

Mokhoa oa ho itšeha oa "Rotary" oa Faygo ke tharollo e ntlafatsang indastering ena, e fokotsa haholo litšenyehelo tsa fektheri mosebetsing, thepa le sekhahla se tšoanelehang. Ho itšeha ha rona ho nka mokhoa o bonolo oa ho itšeha, o sireletsa molomo oa setshelo mme ha o bake li-flakes, o ka netefatsa pheletso e boreleli mme oa u bolokela thepa.

Mochine ona oa ho itšeha o ka sebelisoa bakeng sa makotikoti a polasetiki, linoelo tsa veine, lihlahisoa tsa meriana le tse sebelisoang letsatsi le letsatsi. Thepa e loketseng ea ho itšeha e ka ba PE, PVC, PP, PET le PC, E ka kopanngoa le tlhahiso ea inthanete. Lebelo le phahameng le ka fihla ho 5000-6000BPH.

Ka bokhutšoanyane, e tla ba khetho e nepahetseng bakeng sa tharollo ea hau ea ho itšeha

Ithute haholoanyane -

Mochini o le Mong oa Screw Plastic Extruder

E sebelisoa haholo bakeng sa extruding thermoplastics, joalo ka PE, PP, PS, PVC, ABS, PC, PET le lisebelisoa tse ling tsa polasetiki. Ka lisebelisoa tse sebetsang tse tlase (ho kenyeletsoa moud), e ka hlahisa mefuta e fapaneng ea lihlahisoa tsa polasetiki, mohlala, liphaephe tsa polasetiki, profil, phanele, lakane, li-granules tsa polasetiki joalo-joalo.

SJ Series single screw extruder e na le melemo ea tlhahiso e phahameng, polasetiki e ntle haholo, tšebeliso e tlase ea matla, ts'ebetso e tsitsitseng. Lebokose la gear la "screw extruder" le amohela lebokose la gear le phahameng la torque, le nang le likarolo tsa lerata le tlase, matla a ho jara a phahameng, bophelo bo bolelele ba ts'ebeletso; screw le barrel li amohela lisebelisoa tsa 38CrMoAlA, ka kalafo ea nitriding; enjene e amohela enjene e tloaelehileng ea Siemens; inverter amohela ABB inverter; molaoli oa mocheso o amohela Omron/RKC; Li-electric tsa khatello e tlase li sebelisa motlakase oa Schneider.

Ithute haholoanyane -

PERT phala ea ho futhumatsa fatše

E sebelisoa haholo bakeng sa ho hlahisa PP-R, liphaephe tsa PE tse bophara ba 16mm ~ 160mm, liphaephe tsa PE-RT tse bophara ba 16 ~ 32mm. E na le lisebelisoa tse nepahetseng tse tlase, e ka boela ea hlahisa liphaephe tsa PP-R tsa mufti-layer, lipeipi tsa fiber tsa khalase tsa PP-R, lipeipi tsa PE-RT le EVOH. Ka phihlelo ea lilemo tse ngata bakeng sa extrusion ea liphaephe tsa polasetiki, re boetse re ntlafalitse lebelo le phahameng la PP-R / PE pipe extrusion line, 'me lebelo la tlhahiso ea max e ka ba 35m / min (e thehiloeng holim'a liphaephe tsa 20mm).

Ithute haholoanyane

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu